- Ocean Way Express Mobile App

- Multiload for Windows Loading Program

- Steel Coils Loading Software

- Ship's Squat/UKC/Speed Loss & Tide Calculation Software

- Deflection & DWT Gain/Loss Software

- Draft Survey Software

- Draft Survey Online Software

- Noon Reporter Software

- SMM Voyage Performance Software

- Electronic Deadweight Scale Software

- Maximum Cargo Intake Software

- Cargo Split and Auto Trim Software

- Vessel Floating Position Software

- Multiload Advanced Cargo Securing Software

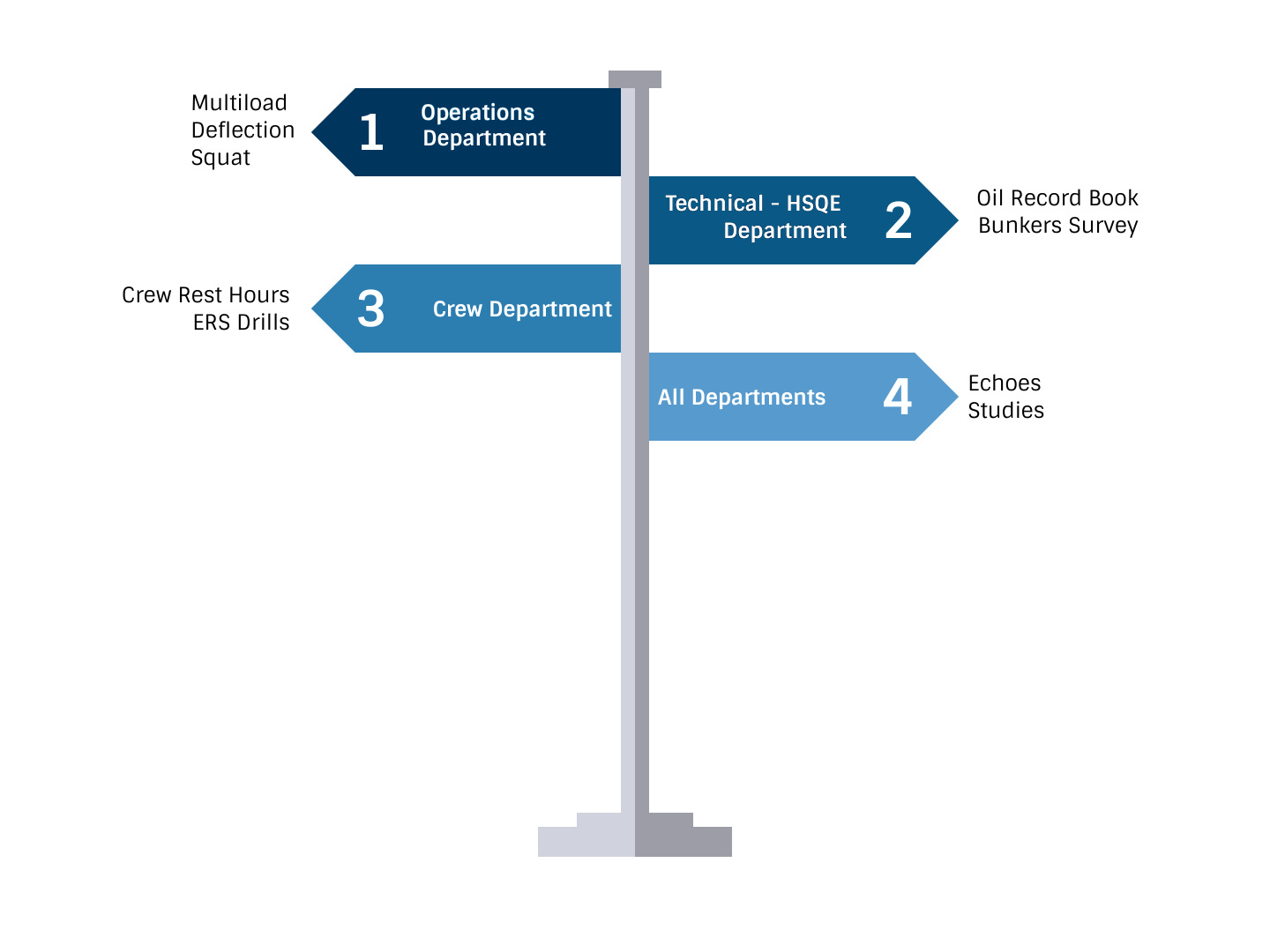

Operations-Chartering Department |

-

Instant access to the Ship Particulars for any chosen vessel of his fleet to review or forward to his mobile contacts and other interested parties.

-

Deadweight Scale Calculations that calculate detailed results for any given Draft, Cargo or DWT.

-

EASYLOAD, an Optimal Stowage Plan Generator using AI for single Bulk Cargo Loadings.

-

Creation of detailed new Chartering Cases and instant calculation of Maximum Cargo Intake that covers all given restrictions.

-

Instant Stowage Plan Generation with low stresses and adequate stability for any Chartering Case.

-

Record keeping of your Recent Chartering Cases for future reference.

-

Comprehensive Reports (PDF) to be forwarded to any of your mobile contacts through e-mail, Viber, Skype etc.

-

SMM unbeatable quality and superb after sales support for the years to come.

-

In case of Multi Cargo Operations that are not supported by Ocean Way Express, we optionally offer SMM Ocean Way Back Office Support.

- More...

|

|

|

|

|

Improved efficiency of operations, judgement and communication.

Ease of use, versatility and additional useful options.

The Base Program offers 43 functions (more than any other loading program).

Approved by all IACS Members.

Type approval by LR & DNV-GL.

Direct damage stability type 3 as per MARPOL/IGC Code.

There are up to 50 Multiload options to choose from.

Full support and free in-house/distant training.

Consultancy support on difficult loading conditions.

Operational in windows network environment.

Office fleet-based version.

Installed on more than 1,000 Bulkers.

- More...

- Draft survey instrument.

- Cargo loading sequence with report (including “free mode” method).

- Air draft calculation from hatches.

- Multiload warning regarding SOLAS Chapter XII- Regulation 14.

- Departure - Arrival Calculation.

- Maximum allowable & actual steel soils loading.

- Detailed steel coils general cargo option.

- Ship loading plan on screen.

- Full support and free in-house/distant training.

- Ship’s girder deflection and deadweight gain or loss.

- Real time loading / Water ballast exchange.

- Printout of N.C.B. / Canadian / Australian form for grain loading.

- Autoload.

- Cargo compartment group definition.

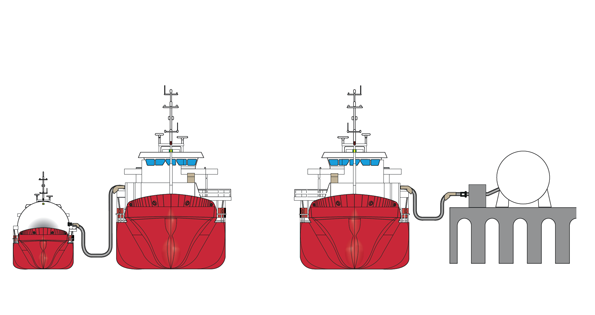

- Real time tanker loading with sensors.

- Oil cargo transfer with report.

- Air draft calculation from manifolds.

- Departure - Arrival calculation.

- Direct damage stability type 3 as per MARPOL/IGC Code.

- Real time tanker loading.

- Worst case damage stability scenario as per VIQ7 Requirements.

-

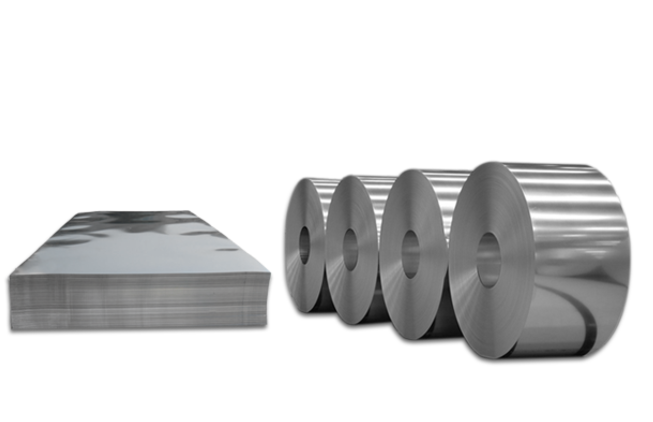

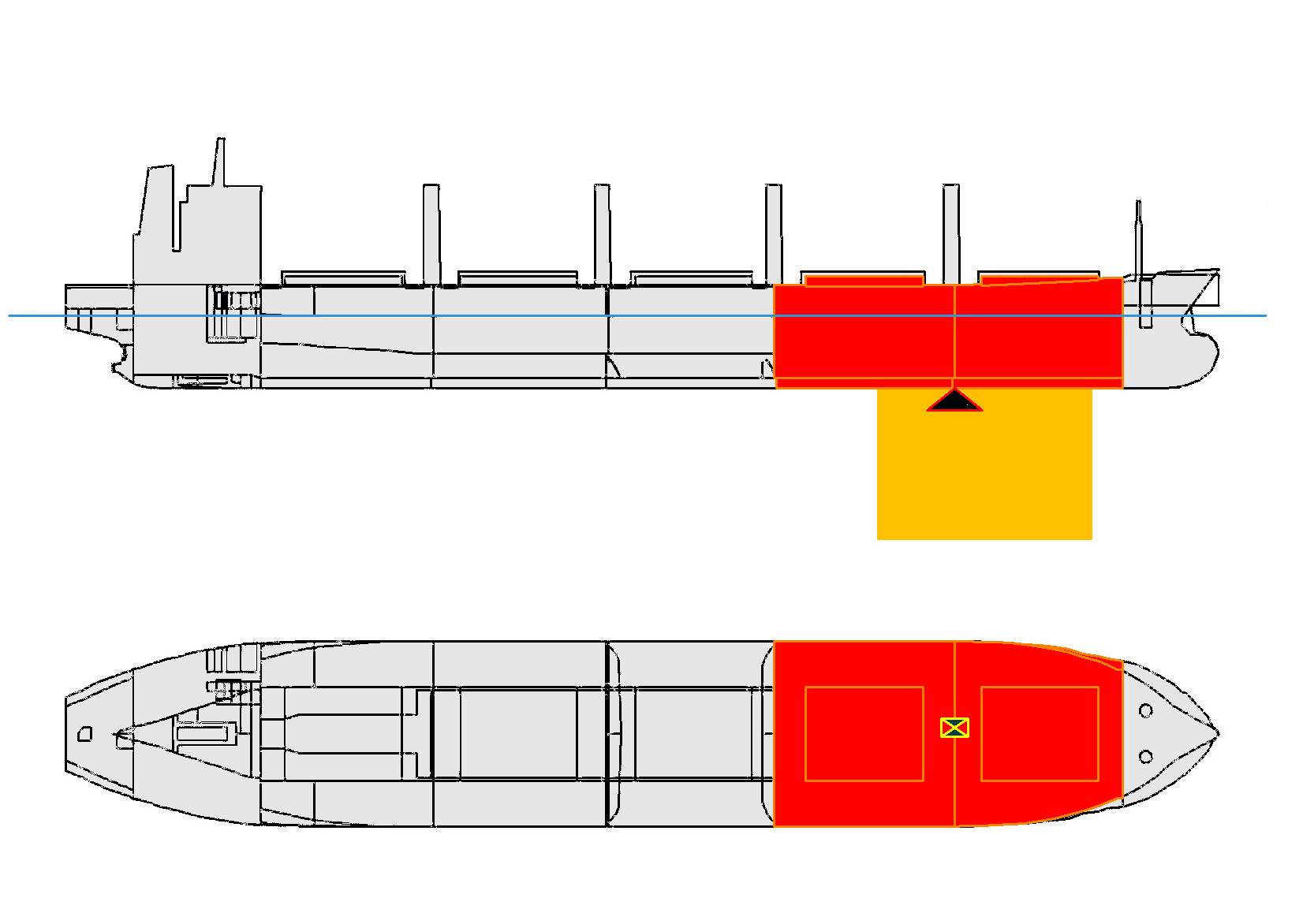

Ship-specific process for increasing & maximising the steel coils and steel products loading per cargo hold (if Combined with Multiload Loading Program and applicable studies).

-

Maximum allowable Steel Coils loading for particular length, diameter and weight of coil for each cargo hold.

-

Actual Steel Coils loading module: An independent calculation for actual steel coils loading for given length, diameter, weight and number of tiers of coils calculating the percentage of local strength/stress level as compared to 100% of Class requirements (ie: 105%, 120%).

-

In one go, you can examine the maximum steel coils loading (local Strength), stowage and final loading condition (drafts, SF, BM) for Multi-port/consignments operations (if Combined with Multiload Loading Program).

-

Full or Partial Loading of coils and break bulk cargoes in any Cargo Hold (if Combined with Multiload Loading Program).

-

Beginning of loading of coils/rows from any longitudinal location in the tank top of each hold (if Combined with Multiload Loading Program).

-

Pictorial view of stowage (if Combined with Multiload Loading Program).

- More...

|

|

|

|

|

|

|

|

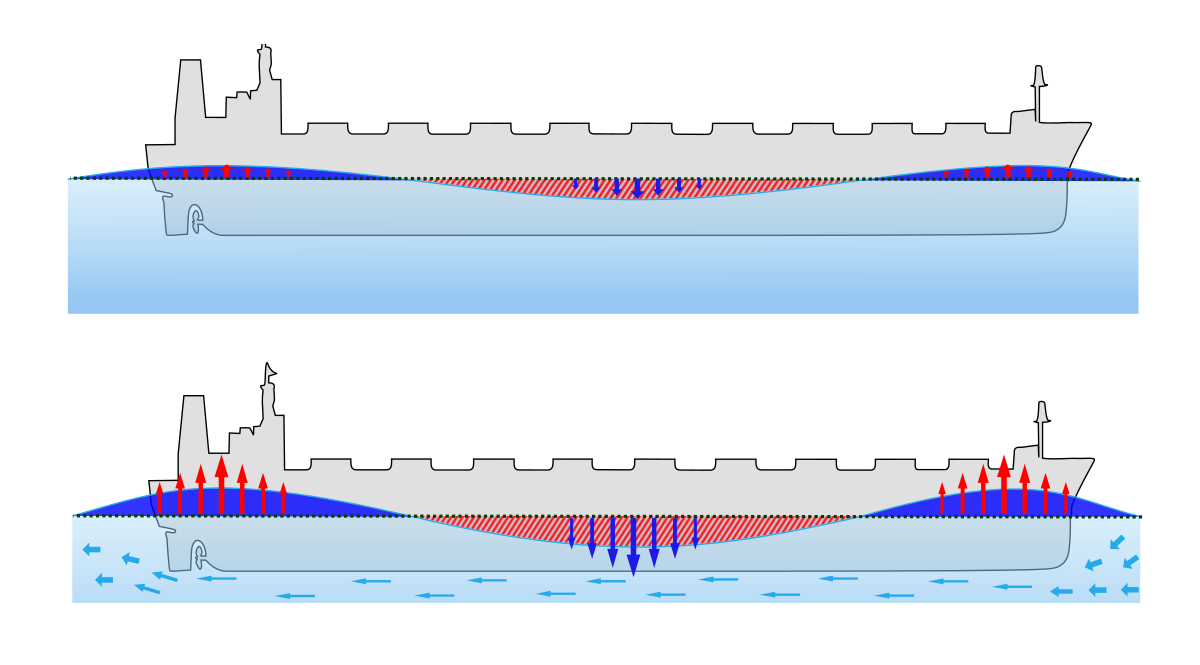

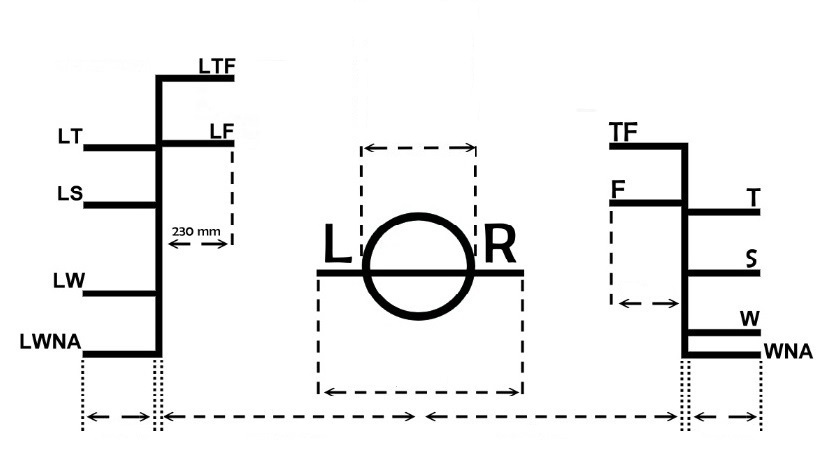

UKC calculation takes into account all the vetting inspection questionnaire/OCIMF requirements.

Tide calculations using UKHO database.

Calculated grounding speed, the safe speed, the grounding area and the loss of speed.

This Option is based on the over than 36 year experience and research of Dr. Bryan Barrass (UK) using his privileged analytical method for the applicable calculations with less conservative calculations as to DWT Margin with positive impact on the cargo intake.

Office fleet-based version with auto-synchronization.

- More...

|

|

|

|

|

|

|

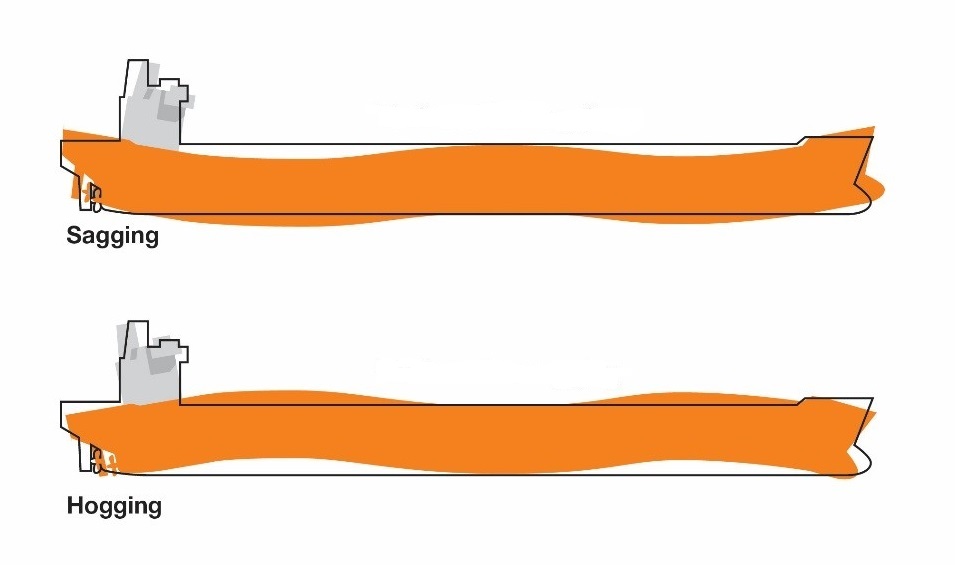

Adjusted draughts of Deflected vessel and comparison to the ones in rigid state for the vessels that are equipped with MULTILOAD.

Thermal deflection due to air-sea water temperature difference.

Intercorrelation with ship's squat in terms of deflected Drafts.

Calculation of deadweight gain or loss depending on the vessel's condition (ie. sagging/hogging).

Analytical bending calculations.

This is especially important when navigating at Plimsoll marks in cold waters (e.g. North Atlantic) with sun.

Automatic synchronization of data between vessels and office (fleet-based).

Office fleet-based version.

- More...

|

|

|

|

|

|

|

Automatic corrections for trim and heel & density.

Instantaneous calculations of DWT items.

Memory of last known weights for each tank brings savings in time and effort for every single draft survey.

Timeline of all the recorded draft surveys

Print-out tailored to each shipping company’s needs.

Clarity & transparency based on official shipyard’s documentation (sounding/calibration tables) endorsed by SMM (UK) Ltd. as 3rd party.

Improved efficiency of operations, judgement and communication.

Automatic synchronization of data between vessels and office (fleet-based).

Office fleet-based version.

- More...

|

|

|

|

|

|

|

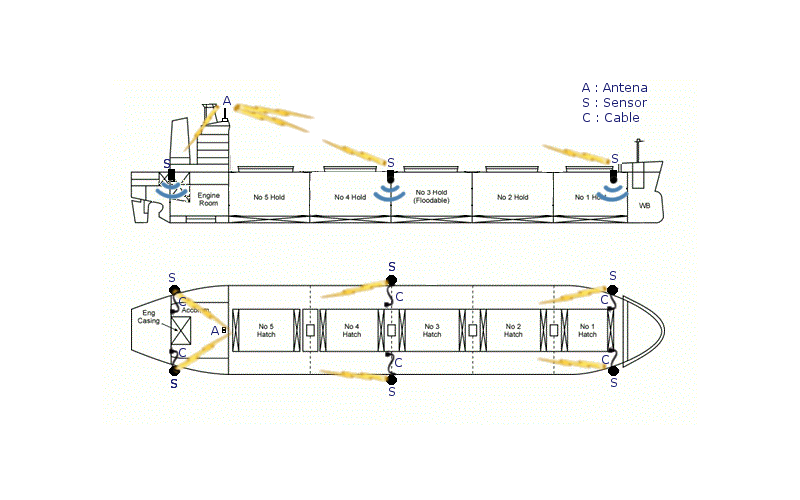

Processing the signals from sensors and generates in turn real time values at design draft reading marks positions.

Real time assessment of cargo loading/unloading quantity.

Cargo operation monitoring.

Restrictions in terms of load zone and port draft and air draft from hatches and radar mast restrictions as warnings for the whole monitoring of operation.

Basis on distance sensors’ measurements and wireless data transmission online to a central Unit for further processing.

Automatic synchronization of data between vessels and office (fleet-based).

Office fleet-based version.

- More...

|

|

|

|

|

Easy transmission of reported data for further processing.

Simple generation of automatic email with all the required data for easy reporting to all the concerned parties.

Minimization of human errors to vessel's reporting due to ship-specific limits and standardization of typing/wording.

Reports of good data quality.

Smooth and care free integration of the stored data to third party software products.

Consistent records of reported data that can be retrieved for any period.

Uniformity of reporting method.

Tailored to company’s reporting Policy.

Office fleet-based version.

- More...

|

|

|

|

|

|

With the software in place, the user can then evaluate the SMM - Voyage Performance against Charter Party terms and provisions.

Overall voyage assessment = Function {Fuel Consumption Calculation, Time Calculation, Charter Party Claims}.

The SMM - Voyage Performance assists by establishing systematic records for the evaluation of the SMM - Voyage performance against Charter Party: fuel consumption calculation, time calculation, Charter Party claim and overall voyage assessment.

For the SMM - Voyage Performance module, the solver is based on the monitoring and reporting of basic parameters during the voyage, their comparison against reference values under actual conditions, charter party terms and warranty conditions.

Office fleet-based version.

- More...

|

|

|

|

|

|

Instantaneous calculation of Hydro data (MCT, TPC) - Displacement - Cargo - Air draft from radar mast - Air draft from hatches for any draft.

Utilities to complement the hydrostatic tables and refine the calculation for determining weight Of cargo onboard Ship for any draft reading.

The risk of losing important ship documentation during handling of hard copies is minimised.

Expenses and delays for retrieving appropriate vessels’ plans or manuals can be avoided.

Clarity & transparency based on official shipyard’s documentation endorsed by SMM (UK) Ltd. as 3rd party.

Automatic synchronization of data between vessels and office (fleet-based).

Office fleet-based version.

- More...

|

|

|

|

|

|

User-friendly load zone DWT Calculation program for determining how much Cargo to load.

Instantaneous calculations of Maximum Cargo Intake for any examined ship-specific Hydros data, Voyage operational profile, Load zones and Port draft restrictions.

Indication of compartment Details.

Ease to use with menus and dialogs for easy operation.

Instant post-fixture decisions.

Upgrade of the already approved Loading Program, without the need for Class Approval.

Automatic synchronization of data between vessels and office (fleet-based).

Office fleet-based version.

- More...

|

|

|

|

|

|

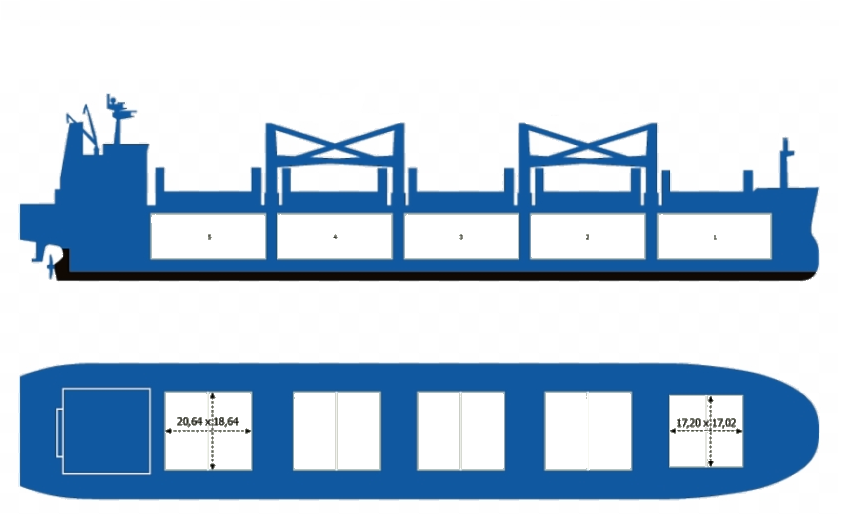

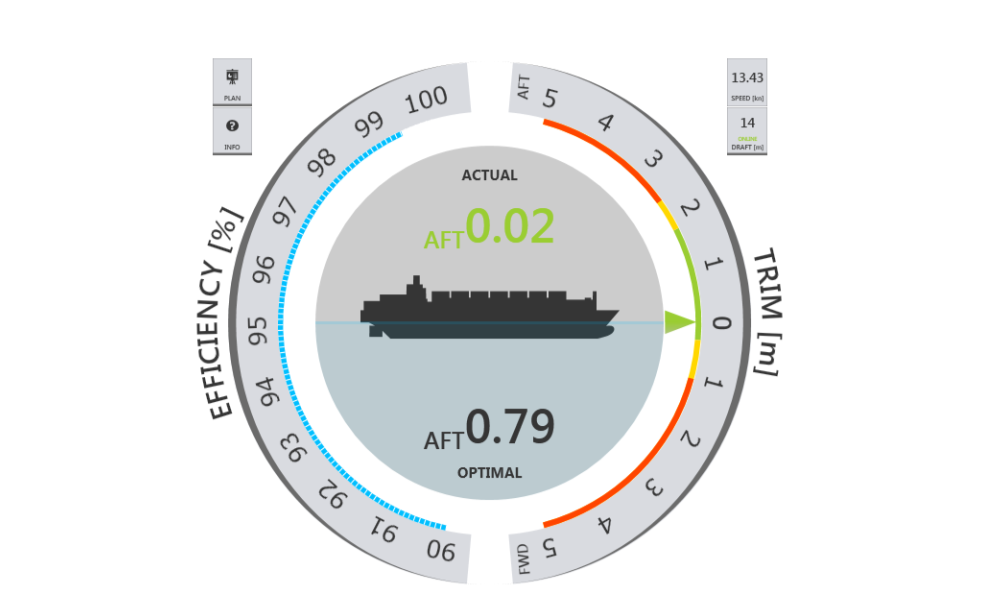

Sophisticated and care-free tool for instantaneous calculation of optimum cargo distribution for achieving the most efficient trim.

Given a quantity of cargo that is yet to be loaded, with this module can calculate how you should split the given quantity between two compartments in order to attain a given Trim.

Upgrade of the already approved loading program, without the need for Class Approval.

Clarity & transparency based on official shipyard’s documentation endorsed by SMM (UK) Ltd. as 3rd party.

Automatic synchronization of data between vessels and office (fleet-based).

Office fleet-based version.

- More...

|

|

|

|

|

|

With the “Vessel Floating Position” module in use, you can easily calculate and provide all info requested by the Charterers/Port agents/Terminals, without requiring retrieving the needed figures from loading manuals and vessels' Plans.

The most critical information of your vessel's floating position (ie. During loading/unloading operations) are fully accessible by anyone.

The risk of losing important ship documentation during handling of hard copies is minimized.

Expenses and delays for retrieving appropriate vessels’ plans or manuals can be avoided.

Automatic synchronization of data between vessels and office (fleet-based).

Office fleet-based version.

- More...

|

|

|

|

|

|

Easy calculations of the deck cargo securing and lashing.

Advanced cargo securing calculations for deck cargo.

In accordance with Annex 13 to the Code of Safe Practice for cargo stowage and securing (the CSS code) from IMO.

Accelerations and balance of forces in semi- and non-standardised lashing arrangements.

Transverse sliding & tipping.

Longitudinal sliding.

Lashing details.

Automatic synchronization of data between vessels and office (fleet-based).

Office fleet-based version.

- More...

|

|

|

|

|

|

Technical-HSQE Department |

Equivalent service to other recognized IACS Class Societies service.

Utilization of the most recognizable salvage engineering software HECSALV since 1992.

Expert witness services by experience ex IACS Class Naval Architects are provided to support owners and underwriters claims.

Effective evaluation of your emergency response plan.

Crew training and shore-based response team.

OCIMF guidelines on capabilities of emergency response services.

Fast decision-making and precision to advising on how to improve situation for cargo and vessel.

Harmonization with all IACS & OCIMF recommendations for the operations of shore-based emergency response services.

24/7 availability for effective and immediate response to emergencies at sea.

- SMM ERS Drill Organizer (Freeware).

- More...

|

|

|

|

|

|

|

|

Automatic corrections for trim and heel.

Calculation of the density of blended bunkers.

Support for customizable setting of the alarm contents levels for each F.O./D.O. tank.

Automatic calculation of the recommended bunkers quantities basis on the abovementioned alarm tanks level.

Insertion of upper sulphur content limits.

Certain colourization of program cells depending on sulphur content.

Clarity and transparency based on official shipyard’s documentation (sounding/calibration tables) endorsed by SMM (UK) Ltd. as 3rd party.

Automatic synchronization of data between vessel and office.

Office fleet-based version.

- More...

|

|

|

|

|

|

|

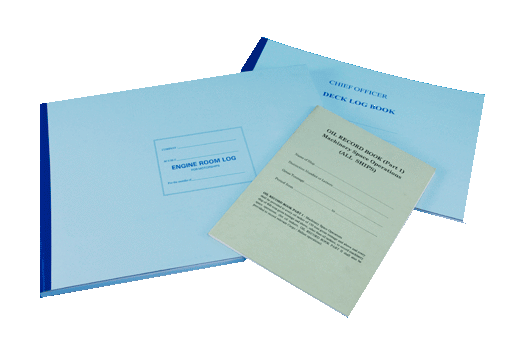

LISCR, Cyprus, Singapore, Bahamas, Malta, Norway, Cayman Islands, Marshall Islands & Hong Kong Flag Administrations accept officially our software solution.

SMM-eORB (Part I) Software consists of the first Electronic Record Book software, which is getting Type Approval certificate from DNV-GL globally.

Check of coordinates against special areas (ie. OWS) & SECAs (ie. Incinerator).

Automatic synchronization of data between vessels and office (fleet-based).

Audit log for all users' activities.

Restrictions in disposal methods of oil residues.

Optional automatic estimation of R.O.B. quantities based on estimated flow rated as derived by D.F.O.C.

Clarity & transparency based on official shipyard’s documentation (piping diagram, capacity plans, IOPP certificates, incinerators/pumps makers’ manuals) endorsed by SMM (UK) Ltd. as 3rd party.

Office fleet-based version.

- More...

|

|

|

|

|

|

|

Harmonization of the daily reported ship consumption figures with the upcoming reported emitted amounts in line with the M.R.V. and D.C.S. Scheme.

Consistent voyage records.

Auto-data input based on the daily reports (noon reports, EOSP, COSP, Inbound, Outbound, etc.) of your current good company’s format received via emails .

Possible integration with other Reporting Systems in place.

Facility for filtering voyages.

EEOI and CII statistics records.

Long experience in vessels’ performance assessment.

Automatic synchronization of data between vessels and office (fleet-based).

Office fleet-based version.

- More...

|

|

|

|

|

|

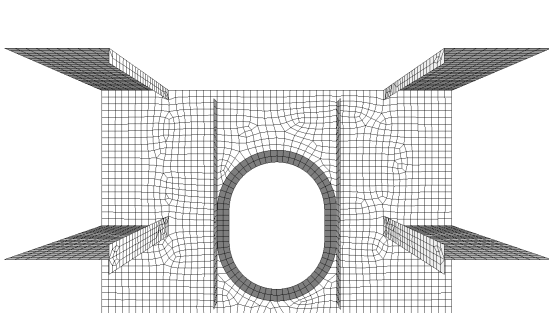

Assurance of full compliance with the new ACP towing/moorings requirements.

Support on the evaluation of existing ship arrangements against new vessel requirements.

New mooring & towing fitting arrangements.

Minimum required under deck reinforcements.

Longstanding experience focusing on your individual ship’s needs/aspects.

Full technical supervision and expertise on every stage of the above-mentioned services.

Finite Element Analysis, if necessary.

- More...

|

|

|

|

Hull structure rating (Maximum Wastage Profile) and onboard inspection program.

Cost efficient, less time consuming for the owners and is based on principles similar to condition assessment programs (CAP).

Relative wastage distribution table-UTM statistical analysis.

The relative wastage ship graphic.

Fatigue assessment.

Relative wastage distribution Table / UTM statistical analysis/Ship graphic.

Assessment for long term fleet planning.

More focused and cost effective future ship maintenance policies.

Linearly extrapolated forecasts for Hull Structure future state.

- More...

|

|

|

Consists of four modules: Spare Parts, Ship Maintenance, Survey Status, Manning

Warning indicators for overdue surveys, recommendations, maintenance items etc.

Specific to company's everyday office requirements.

Office use only-No extra workload for seafarers.

User-friendly.

Concise decision making reports.

Overview of the entire fleet.

Minimum possible input effort.

Fleet based reporting system.

Easy creation of initial ship database.

- More...

|

|

|

|

|

Crew Department |

Support for work rest hours print-out as per Marshall Islands requirements (indicate rest hours instead of work hours).

Input/calculation basis on rest hours basis.

Non-conformance statistics - individual N/C printout report per month.

Facility for change of vessel’s flag and name anytime by the User.

In line with the 2010 "Manila Amendments" for 24H / 7D Exceptions - STCW 2010 - MLC 2006.

The main printout can be customized/translated given certain limitations.

Checks on every 24hr basis.

More than 2,000 installations on all types of ships.

Office fleet-based version.

- More...

|

|

|

|

|

|

|

Every Department |

Ability to upload monitoring/analysis/recordkeeping & repair planning related Documents (pdf, photos, excel files, etc.) or reports either from SMM Applications or 3rd Party Software ashore and onboard to predefined folders.

Notification to registered users, when any new document is uploaded along with a direct link for easy access to the recent file.

Audit Log for all users' activities.

This web-based module is designed to ensure documents are shared easily and securely.

Comprehensive search facility.

Inter-connection with reporting & dashboard Server via the database and API layers.

Fleet-based version.

- More...

|

|

|

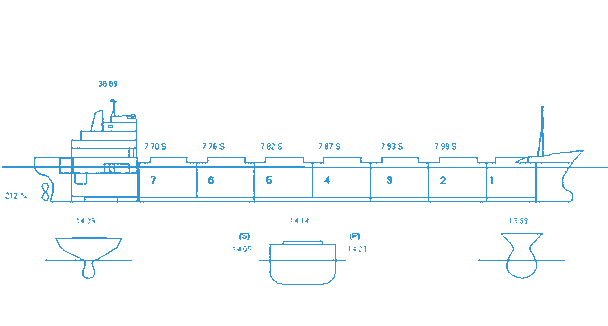

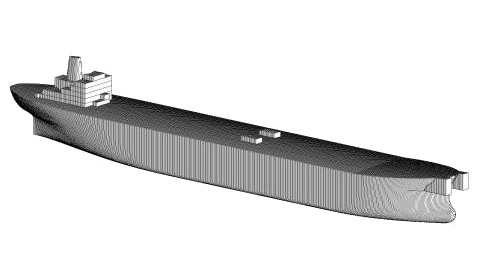

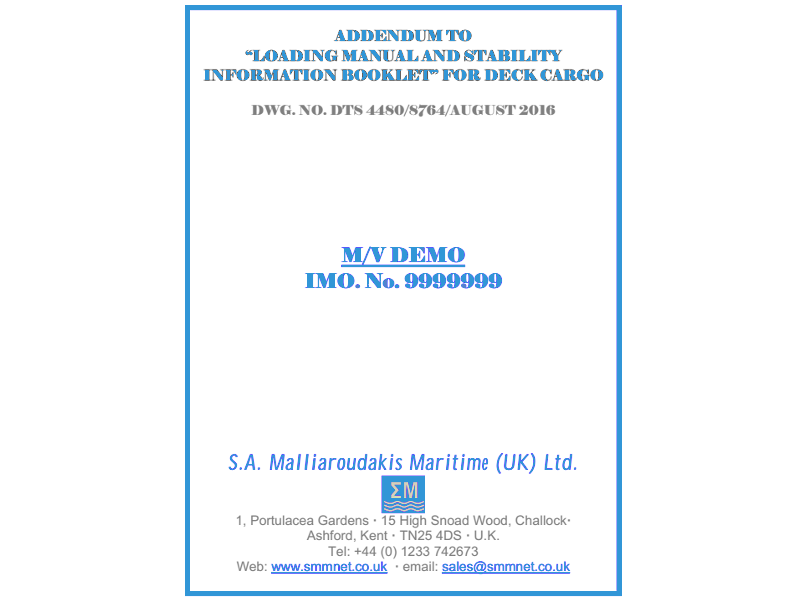

Longitudinal strength manuals.

Trim & Stability booklets.

Grain loading manuals.

Container loading manuals.

Timber loading manuals.

Addendum to loading manuals for deck cargo.

Addendum to loading manuals due to deeper draft (B-60).

Addendum to loading manuals for steel products (Steel Plates, solid bars, Bandle of small Pipes, Steel Sections, Billets) for maximizing vessels' operational capabilities.

Increase & Maximise the Steel Coils and Steel Products Loading per Cargo Hold.

Damage stability calculations for regulation 27 of ICLL 1966 and the 1988 protocol to the ICLL 1966.

Probabilistic damage stability analysis of SOLAS Chapter II-1 Part B-1.

Damage stability for Dry / Tanker / Chemical carriers.

- More...

|

|

|

|

|

Calibration of tanks.

Panama Canal Authorised Person Services.

Steel coils/Slabs-Billets loading & Cargo Securing Manuals.

Air Draft & Deadweight Tables.

Emergency towing booklet.

Damage Control Plan & Booklet.

Garbage management plan.

SOPEP (Shipboard Oil Pollution Emergency Plan) & PCSOPEP (Panama Canal Shipboard Oil Pollution Emergency Plan).

Water ballast management & Biofouling management plans.

International tonnage measurement 1969 (GRT & NRT).

SEEMP Part I & Part II (Ship Energy Efficiency Management Plan).

Recovery of persons from water.

- More...

|

|

|

|

|

All Rights Reserved 1986 - © www.smmnet.com